Polishing or Grinding Tubes on a Contract Basis

We offer the polishing and brushing of customer-supplied tubes on a contract basis.

With four automatic special machines, we provide contract polishing services for metal tubes of all kinds:

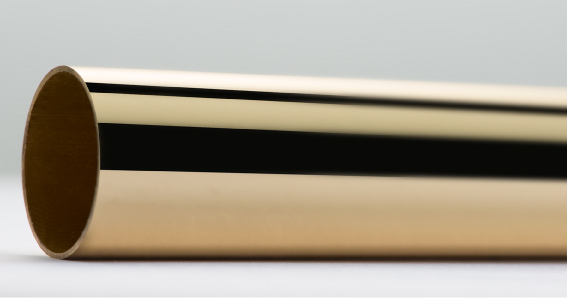

- Brass tube: Polishing, Brushing, Grinding, Satin Finishing

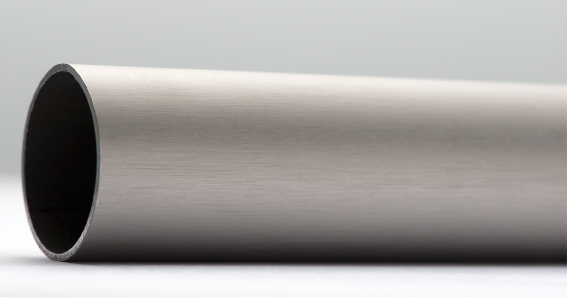

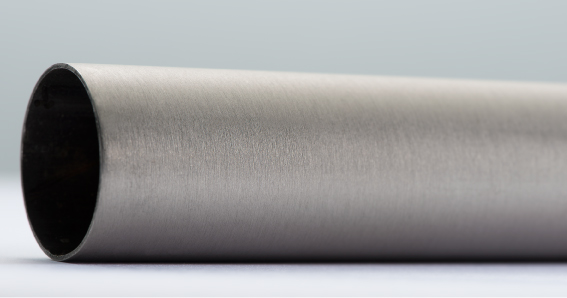

- Stainless Steel tube: Polishing, Brushing, Grinding, Satin Finishing

- Copper tube: Polishing, Brushing, Grinding, Satin Finishing

- Steel tube: Polishing, Brushing, Grinding, Satin Finishing

Maximum Diameter: 200mm

Maximum Length: 6500mm

Your Advantages:

- Handling of both large and small series

- High cost-effectiveness due to high process speed and automation

- Brushing, Satin Finishing, Grinding, both radially and longitudinally

Pickhardt & Gerlach has the capability to polish large as well as small series of metal tube, such as stainless steel tubes, brass tubes, copper tubes, or steel tubes on an industrial scale or brush, satin finish, or grind tubes with various grain sizes. Due to high levels of automation and process speed, P&G offers its customers high cost-effectiveness in tube contract processing.

Polishing tubes:

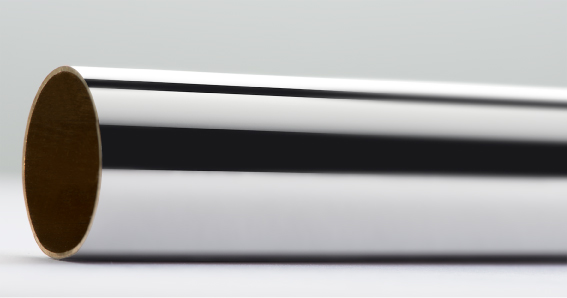

Metal round tubes are polished at P&G in a fully automatic special polishing system with up to 8 stations simultaneously. By combining hard grinding belts and soft polishing discs, we achieve maximum impact on the metal surface, allowing for the smoothing of larger grooves, scratches, and pores. Thus, it is possible to meet all customer requirements regarding surface quality as well as the cost-effectiveness of the polishing process. Polishing metal tubes, such as stainless steel tubes, brass tubes, copper tubes, or steel tubes, requires expertise and experience in handling optical surfaces. Pickhardt & Gerlach has been dealing with the processing of metallic surfaces for more than 75 years, catering to the diverse requirements of various industries: bathroom fittings, lighting industry, window decoration and sun protection, furniture construction, automotive industry, and many more sectors.

Brushing, Grinding, or Satin Finishing Tubes:

Brushing, Grinding, Satin Finishing: Three terms, one meaning. The surface of metal tubes, such as brass tubes, copper tubes, stainless steel tubes, or steel tubes, is given a finish that can vary in intensity based on the grain of the grinding belts. Additionally, the direction of the finish can be determined. P&G offers both radial brush strokes and longitudinal brushing. Upon request, polishing and brushing discs can be combined at the 8 different stations of the polishing system to further smooth the ground surface. P&G offers different grain sizes for grinding, brushing, or satin finishing the pipe surfaces, according to customer preferences. Typical and common grain sizes of grinding belts are K180, K240, K320, and K500. The lower the grain number, the coarser the finish. K500 (grain size 500) results in a very finely satin-finished surface where the individual brush strokes are barely distinguishable to the naked eye.

Keywords:

- Brass tubes: Polishing, Brushing, Grinding, Satin Finishing

- Stainless Steel tubes: Polishing, Brushing, Grinding, Satin Finishing

- Copper tubes: Polishing, Brushing, Grinding, Satin Finishing

- Steel tubes: Polishing, Brushing, Grinding, Satin Finishing